ERS system structure and features

ERS system structure and features

How ERS works and features in 5 minutes

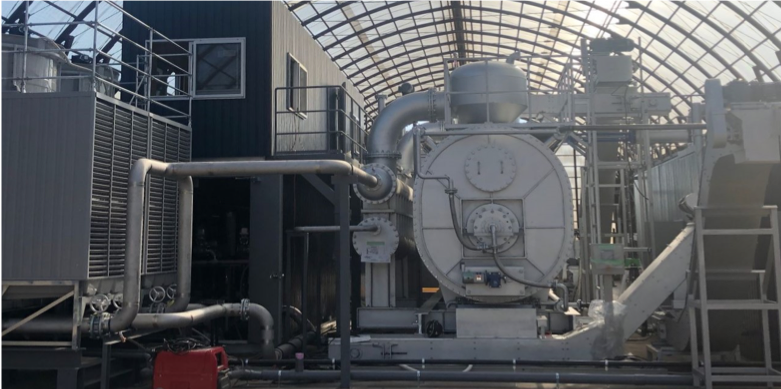

ERS system structure

ERS system structure

The processing capacity per ERS unit ranges from 0.5 tons to 50 tons and the unit does not emit drain and odors throughout the process.

ERS Size

| Maximum processing weight per day (in 24-hour operation) |

|

| Approx. volume of chamber (㎥) | |

| Approx. area size required (m) | Width(W) |

| Depth(D) | |

| Height(H) | |

| ERS-1U | ERS-2U | ERS-3U | ERS-4U | ERS-5U |

| 2 ton/day | 4 ton/day | 8 ton/day | 15 ton/day | 25 ton/day |

| 3.15 | 5.93 | 10.25 | 15.51 | 19.81 |

| 6.3 | 8.3 | 9.9 | 14.1 | 15.3 |

| 3.2 | 3.2 | 3.4 | 4.1 | 4.3 |

| 3.8 | 4.2 | 4.6 | 4.7 | 4.8 |

*Actual maximum processing weight depends on various factors including the kind and moisture content of input material to be processed as well as the use application of output.

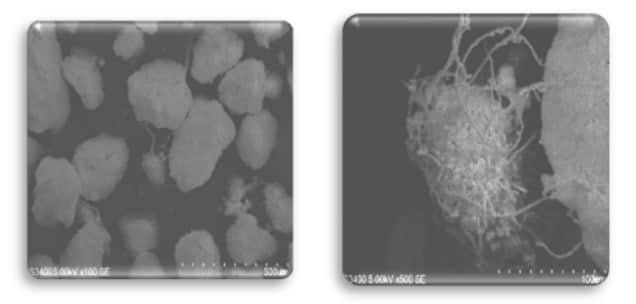

PATENTS

ERS utilizes specific microbes collected from the local soil for its fermentation and drying process. 3 types of microbes were specified and deposited to the International Patent Organism Depositary (IPOD) at the National Institute of Technology and Evaluation (NITE), Japan.

These 3 microbes have a symbiotic relationship and deposited as the first-ever symbiotic microbes to the IPOD.

Deposit date: March 14, 2001

IPOD Patent No.:

FERMBP-7504, FERMBP-7505, FERMBP-7506

Device patents

- Microorganism, Composition Containing Microorganism, And Method For Manufacturing Organic Fertilizer Using The Microorganism

[JP] Patent No. 4153685 (July 11, 2008) - Apparatus and method for treating organic matter including harmful microorganisms

[JP] Patent No. 6829468 (January 26, 2021)

[CN] Patent No. ZL201880052013.X (August 9, 2022) - Apparatus And Method For Producing Fuel By Fermenting And Drying Object To Be Treated

[JP] Patent No. 6763575 (September 14, 2020)

[CN] Patent No. ZL 2018 8 0052014.4 (September 10, 2021)

[PH] Patent No. 1-2020-500383 (April 19, 2022) - Fuel Production Device For Biomass Burner And Manufacturing Method For Same

[JP] Patent No. 6763576 (September 14, 2020)

[CN] Patent No. ZL2018 8 0058171.6 (September 10, 2021)

[PH] Patent No. 1-2020-500516 (November 10, 2022) - Apparatus and method for treating shell

[JP] Patent No. 7015044 (January 25, 2022) - Device and method for manufacturing de-oiled dry product

[JP] Patent No. 7138329 (September 8, 2022) - Apparatus and method for treating plastic-packaged food waste

[JP] Patent No. 7114064 (July 29, 2022)

[CN] Patent No. ZL201980039470.X (October 21, 2022) - Device and method for treating digested liquid from methane fermentation of organic material

[JP] Patent No. 7083160 (June 2, 2022) - System and Method for treating excrement of livestock

[JP] Patent No. 7178697 (November 17, 2022)

[Australia] Patent No. 2019369118 (December 8, 2022)

[US] Patent No. 11618704 (April 4, 2023)

[Denmark] Patent No. PA202100379 (May 10, 2023) - Apparatus and method for producing fuel for burning furnace

[JP] Patent No. 7246707 (March 17, 2023) - Boiler device and organic waste treatment device provided with same

[JP] Patent No. 7260154 (October 10, 2023)

[IN] Patent No. 442090(August 1, 2023)

[CN] Patent No. ZL202080039568.8 (September 13, 2024) - System and method for treating oil sludge

[JP] Patent No. 7175005 (November 10, 2022)

[US] Patent No. 11753325 (September 12, 2023)

[CN] Patent No. ZL202080032078.5 (December 8, 2023) - Drying device for porous substance, hydrogen production device comprising same, and method for drying porous substance

[JP] Patent No. 7146277 (September 26, 2022)

[CN] Patent No. ZL2020080054877.2 (June 27, 2023)

[IN] Patent No. 441615 (July 31, 2023)

[Indonesia] Patent No. IDP000088627 (July 20, 2023)

[Australia] Patent No. 2020376194 (November 30, 2023)

Advantages of use of ERS

Advantages of use of ERS

-

High speed fermentation and drying process

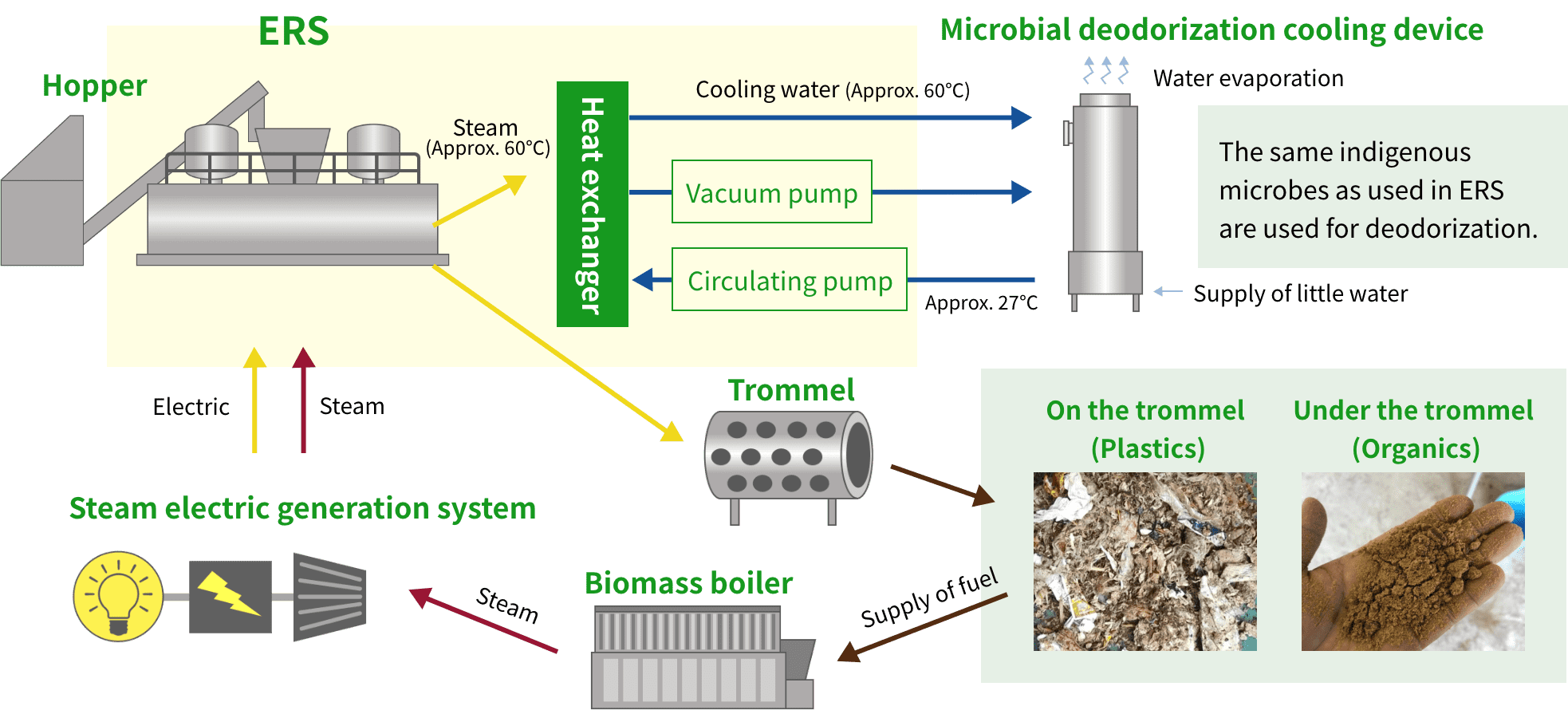

Internal pressure of the ERS main body is mechanically reduced to get the boiling temperature down to 50 to 70 ℃. It helps the patented microbes inside ERS to quickly ferment and dry the input waste even with a high water content.

-

No drain and odor emissions

Drain facilities are no need as moisture from waste is collected and evaporated by microbial deodorization cooling device in ERS system. Ammonical odor from waste is decomposed by specific microbes functioning inside the ERS device in a vacuum environment.

-

Advancing waste recycling

ERS system converts various kinds of waste into high-quality valuable outputs with uniformly controlled degree of fermentation and moisture content. The outputs can be used as fuel, compost, fertilizer, feed, and livestock litter.

-

Reducing greenhouse gas emissions

The reduction of moisture content and size of waste by ERS process leads the reduction of GHG emissions in incineration when incinerating equipment is used.

-

No need of pre-segregation

Able to treat mixed waste without segregation work and reduce human sanitary risk. Easy to segregate after treatment by trommel (sieving tool).

-

No need of replenishing microbes with no bio-hazardous risk

ERS uses specific microbes collected from soil on-site for fermentation and drying process. There is no biological risk to microbial environment where ERS is installed.

-

No need of moisture adjustment

Adding moisture adjustment agents and taking dewatering process are no need to do as ERS system is good at treating organic waste with a high water content.

-

Waste-to-energy

The combination of ERS and power generation systems makes in-house use and/or sale of electricity possible.

-

Advantages of combination use

By using ERS system together with existing facilities (incinerators, methane fermentation facilities, or compost depots), the user will receive various benefits including the reduction of waste treatment cost and environmental burden.

What makes ERS different

What makes ERS different

| Generation of steam and electricity |

|---|

| Fermentation and drying(Fermenting at 65℃) |

| Sterilization of dead livestock(Heating at 90℃) |

| Cooling |

| Emission of odors and drain |

| Drying |

| Applications of processed resource |

| Usability as biomass fuel |

| Emission of GHG |

| Necessity of pre-segregation |

| Capability of segregation after processing |

| Necessity of subsequent material for fermentation |

| Time required for composting |

| Land space required for installment |

| Operability of device |

ERS

|

Conventional rendering

|

Conventional composting

|

Tunnel composting

|

|

|---|---|---|---|---|

| Generation of steam and electricity | 〇 | × | × | × |

| Fermentation and drying(Fermenting at 65℃) | 〇 | × | 〇 | 〇 |

| Sterilization of dead livestock(Heating at 90℃) | 〇 | 〇 | × | × |

| Cooling | 〇(Vacuum cooling) | 〇(Open cooling) | × | × |

| Emission of odors and drain | None | Emitting | Emitting | None |

| Drying | 〇 | × | 〇 | 〇 |

| Applications of processed resource | Fuel・Fertilizer・Feed・Livestock Litter | × | Fertilizer | Fuel |

| Usability as biomass fuel | 〇 | × | × | 〇 |

| Emission of GHG | Least | More than ERS | More than ERS | More than ERS |

| Necessity of pre-segregation | None | Necessary | Necessary | None |

| Capability of segregation after processing | Capable | Not capable | Not capable | Not capable |

| Necessity of subsequent material for fermentation | None | None | Necessary | Necessary |

| Time required for composting | 1 day at earliest | Not able to compost | 2 to 6 months(Easily affected by climatic condition) | Approx. 20 days |

| Land space required for installment | Smallest | Larger than ERS | Larger than ERS | Larger than ERS |

| Operability of device | Easy | Complicated (Special trained operators are required) | Easy (But experience is required) | Easy (But experience is required) |

Procedures to get ERS in your business

Procedures to get ERS in your business

Discussion

Carefully listening to what you currently tackle with and what you want to make possible regarding material recycling or waste treatment, we will offer the best solution for your business.

Oder placement

Right after taking an order from you, we will start detailed design for manufacturing ERS system.

Transportation, installation and commissioning

All appliances are delivered using best logistics. Installation and commissioning are conducted on-site.

Operation and maintenance

Operating situation of ERS system can be monitored in real time using PC or smartphone. Alerts are sent by e-mail when any malfunction of the system occurs.

Approximate delivery time is normally 6 months, but it fluctuates largely depending on social situation and other reasons. Thank you for your understanding.