Soil Fermentation Deodorization: Contributing to Local Communities Through Land Improvement Using Livestock Waste Treatment Technology

— Launching a New Project to Address Odor Pollution Caused by Livestock Manure and Incomplete Composting —

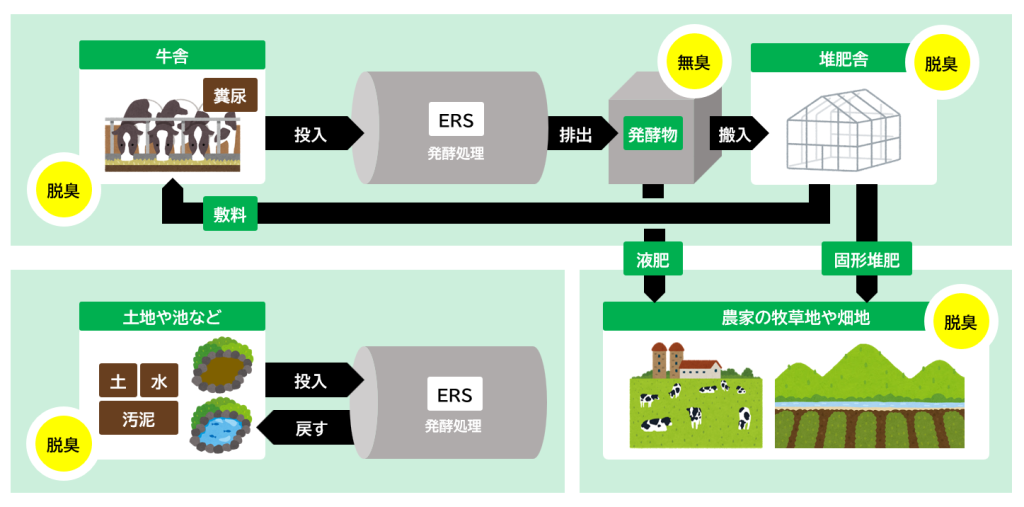

JET Corporation (Chiyoda-ku, Tokyo), the developer and manufacturer of the ERS – Rapid Fermentation & Deodorization Resource System,

has confirmed sustained deodorization effects in soils where liquid fertilizer and bedding material derived from livestock manure were applied.

The verification was conducted at partner sites such as Beru-chan-tachi no Ouchi Co., Ltd. (Shimonoseki City, Yamaguchi Prefecture)

and Top Farm Co., Ltd. (Saroma Town, Tokoro District, Hokkaido).

Furthermore, by fermenting odor-contaminated soil itself with ERS and returning it to the land,

similar deodorization results were achieved.

Building on these findings, JET launched a new business initiative in November 2023

to offer ERS-based land improvement solutions to local governments.

.png)

1. Introduction | The Link Between Odor and Land Value

Livestock manure, when properly managed and fermented, can be utilized as valuable agricultural resources such as compost or soil conditioners.

However, in regions with high livestock density, repeated application of insufficiently fermented manure has led to serious odor problems.

These odors affect not only farmworkers and local residents but also tourists unfamiliar with such environments.

Moreover, as foreign investment and tourism increase, persistent odor pollution can prevent rural regions from realizing higher land values,

ultimately reducing farmers’ potential income.

To address this issue, it is essential to remove odor sources directly from the soil and maintain long-term deodorization effects with minimal labor.

2. Demonstration ① | Beru-chan-tachi no Ouchi Co., Ltd. – Liquid Fertilizer Results

Installed in March 2023, Beru-chan-tachi no Ouchi Co., Ltd. uses ERS to convert dairy cow manure into odorless liquid fertilizer.

In response to declining milk demand, the company introduced ERS to diversify outputs—

not only compost and bedding, but also liquid fertilizer, reducing fuel use and overall operating costs.

After seven months of continuous operation, in October 2023,

the facility achieved the planned processing targets and confirmed the complete elimination of odors.

The deodorization effects were sustained even inside the composting facility.

The company now plans to sell its liquid fertilizer externally in addition to on-site use.

| Item | Details |

|---|---|

| Material | Dairy cow manure |

| Capacity | 25 tons/day |

| Equipment | ERS Type 5U |

| Output | Liquid fertilizer / Compost |

| Location | Shimonoseki, Yamaguchi Prefecture |

| Installation | March 2023 |

| Subsidy | Livestock and Dairy Productivity Improvement Program |

| Note | Member of Yamaguchi Prefecture Dairy Cooperative Association |

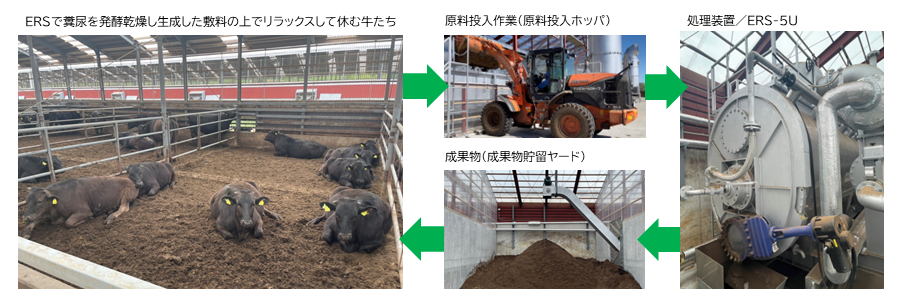

3. Demonstration ② | Top Farm Co., Ltd. – Solid Material Results

Top Farm Co., Ltd., which practices circular agriculture emphasizing animal welfare,

installed ERS in March 2022 to process beef cattle manure into bedding material.

The company highlights that “environmental investment has become a key factor in consumers’ purchasing decisions

as corporate contributions to sustainability gain attention.”

By fermenting and drying manure, Top Farm reuses the material as bedding and compost,

and distributes it to neighboring farms as a fertilizer resource.

Odor, once considered unavoidable in cattle barns, has been eliminated—

creating a comfortable environment for both animals and visitors.

After 19 months of operation, the facility confirmed consistent odor-free results and lasting deodorization.

| Item | Details |

|---|---|

| Material | Beef cattle manure |

| Capacity | 75 tons/day |

| Equipment | 3 units of ERS Type 5U |

| Output | Bedding material |

| Location | Tokoro District, Hokkaido |

| Installation | March 2022 |

| Subsidy | Livestock and Compost Distribution Support Program |

4. Technology | Sustained Deodorization with Beneficial Microorganisms

JET’s ERS (Rapid Fermentation & Deodorization Resource System) performs aerobic microbial fermentation

to decompose odor-causing substances within just a few hours in a sealed chamber.

While conventional manure composting may take several months, ERS converts manure into odorless fertilizer or bedding in a single day.

The system not only deodorizes livestock facilities but also improves soil when ERS-treated compost is applied.

Even odor-contaminated soil can be fermented using ERS and returned to the field,

where the resident microorganisms continue to work without replenishment or replacement,

providing long-lasting deodorization effects.

The Five Key Benefits of ERS Outputs

- Aerobic Fermentation – Produces soil-friendly fertilizer favored by farmers.

- Wastewater Reduction – Microbial fermentation heat evaporates moisture.

- Odor Suppression – Fermented, sterilized outputs prevent odor in composting facilities.

- Shorter Processing Time – Significantly reduces methane generation and composting period.

- Lower Greenhouse Gas Emissions – Rapid fermentation minimizes CO₂-derived methane release.

5. Outlook | Toward Mobile ERS Units

JET plans to develop mobile ERS systems, enabling on-site deodorization where odor issues already exist.

By bringing ERS directly to polluted locations—ponds, rivers, or landfill sites—

JET will expand its capability to address regional environmental challenges more flexibly.

The company remains committed to converting diverse organic wastes—

including household garbage, diapers, sludge, livestock manure, vegetable residues, food waste,

construction debris, and pruning branches—into valuable local resources,

maximizing environmental efficiency and contributing to the realization of a circular society.

6. System Overview

ERS utilizes indigenous microorganisms found near installation sites

to sterilize, ferment, and dry organic materials within one day.

The resulting low-moisture products can be used as fuel, compost, fertilizer, feed, or bedding,

supporting zero-emission operations.

Core Technology – Selective Use of Environmental Microorganisms

- Selectively cultures naturally occurring microbes from local soil.

- Once fixed inside the system, microbes require no replenishment or replacement.

- Even after shutdowns, reactivation requires no microbial maintenance.

Features

- Simple structure with minimal pre- or post-treatment steps.

- Uses naturally occurring microbes – no imported cultures or replacements required.

- Low maintenance and high durability.

- Compact footprint and low facility cost.

- Zero wastewater discharge.

- Significant waste volume reduction and lower transport cost.

- Easy handling due to dried outputs.

- Generates nutrient-rich feed or fertilizer with market value.

- Reduces CO₂ emissions and easily adapts to existing facilities.

ERS Product Lineup

Available in five sizes, with maximum daily capacities tailored to user needs.

Patent Information

- Microorganisms, Microbial Compositions, and Organic Fertilizer Production Methods Using These Microorganisms

[Japan] Patent No. 4153685 (Registered July 11, 2008) - Fuelization Apparatus and Method via Fermentation Drying of Organic Materials

[Japan] Patent No. 6763575 (Registered September 14, 2020)

[China] ZL2018 8 0052014.4 (Registered September 10, 2021)

[Philippines] 1-2020-500383 (Registered April 19, 2022)

All microorganisms used in ERS are patented strains deposited with

the NITE Patent Microorganism Depository (IPOD) in Japan.

ERS utilizes three specific strains isolated from local soil environments,

selected for their exceptional fermentation and deodorization performance.